Ho seha seriti se hanyetsang semityrant Conveyor bakeng sa mochini o sehiloeng oa masela

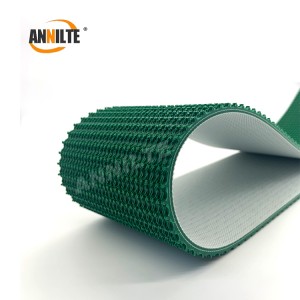

Belt e thibelang Pundlect Pundor ke mofuta oa lebanse ea Convelor, e bolokang ts'ebetso ea mantlha ea lebaleng le hahiloeng ka ho fetisa, ka hona e sebelisoa masimong a mangata a indasteri.

TLHOKOMELISO EA PO 5.0 MM PONTYR BENVER

| Paterone | Matt | Mmala | Pepenene + tšoeu |

| Mohlala | A-P5t | Mocheso | -20-80 |

| Lintho tse bonahalang | PU | Botsitso ba morao | Ho joalo |

| Botenya [mm] | 5 | Bokaholimo ba ho koata HardnessDiameter [mm] | 85 |

| Boima [KG / M2] | 5.1 | Boholo ba Tensile matla [n / mm] | 150 |

| Malapha [mm] | <= 3300 | Qobella ho 1% elongation [n / mm] | 10 |

| Sebopeho | 4pg | Ts'ebeliso e khothalelitsoeng | Line Line, ETC |

Melemo ea rona ea sehlahisoa

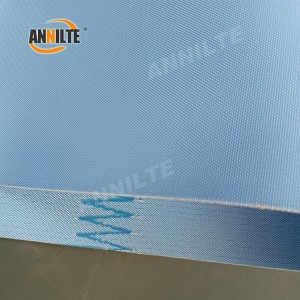

1, Ho amohela theipi e hloekileng ea raw, e kenyelletsa thepa ea polymer, bonolo bo phahameng, boiketlo bo botle, bo botle, bo botle bo eketsehileng ka 50%;

2, Manonyeletso a sebelisa Thegency VulCanization Vercaliction VulCanization, matla a ho tiisoa ke 35%, leqhubu le phahameng la manonyeletso le le bohlokoa;

3, Baetsi ba Lihlahisoa, Lipuisano tse lekaneng, tse felletseng, likhato tse 85, likhato tse 92 bakeng sa mefuta e mengata ea mabanta, bophelo bo bolelele.

Maemo a sebetsang

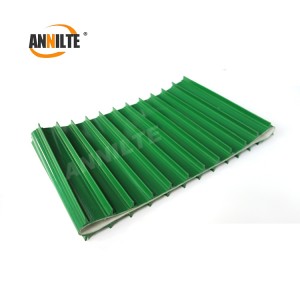

Indasteri ea mochini:Ma-mabanta a sehiloeng a pu a hanela indastering ea mochini o sehiloeng e etsa hore mabanta a se ke a senyeha nakong ea sehatso, e ntlafatsa ts'ebetso ea tlhahiso.

Indasteri ea lijo:Mabanta a sehiloeng a pu a hanela ho fetisa thepa ea lijo le lihlahisoa tsa bona tse thibetsoeng le litsi tsa oli tsa indasteri ea lijo.

Indasteri ea khalase:Libano tsa khalase, tse thibelang Punte tse Khahlano le Punte tsa Pu

Khothatso ea boleng ba boleng ba phepelo ea phepelo

Sehlopha sa R & D

Anclilla o na le sehlopha sa lipatlisiso le sa ntlafatso se nang le litsebi tsa 35. Ka mekhoa e matla ea mahlale le koetliso ea ntlafatso, re fane ka lits'ebeletso tsa ho tsamaisa tšepe likarolo tsa 1780, 'me re boetse re amohela bareki ba 20,000. Ka boiphihlelo bo holileng ba r & d le tloaelo, re ka kopana le litlhoko tsa tloaelo tsa maemo a fapaneng a indasteri e fapaneng.

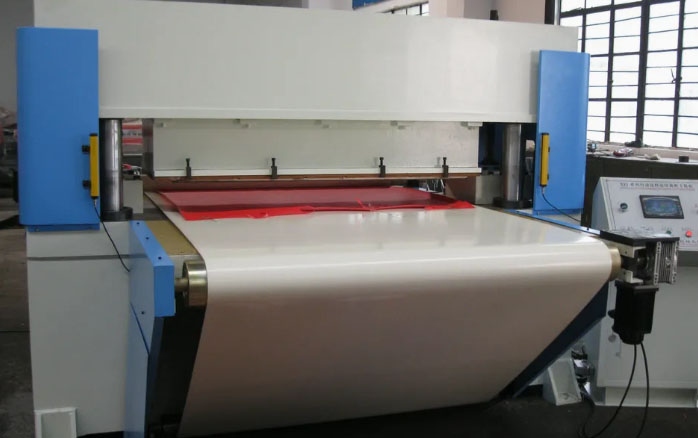

Matla a Tlhahiso

Anclitte e na le litheko tse 16 tsa tlhahiso ka botlalo tse tsoang Jeremane ka thupelo ea eona e kopaneng, le mela ea tlhahiso ea lihlopha tsa backup ea tšohanyetso. Khampani e tiisa hore setoko sa mefuta eohle ea thepa e tala ha se ka tlase ho lisekoere-k'hilomithara tse 24 ho araba litlhoko tsa moreki ka nako e loketseng.

AnniltekeConvelor lebantaMoetsi le lilemo tse 15 tsa boiphihlelo Chaena le Setifikeiti sa ISO seterezation. Re boetse re moetsi oa sehlahisoa sa machaba oa khauta.

Re fana ka tharollo e mengata ea lebalekeng tse nang le mekhoa e mengata e tlas'a molao oa rona, "Annilte."

Haeba u hloka tlhaiso-leseling e tsoelang pele mabapi le mabanta a rona, ka kopo u se tsilatsile ho ikopanya le rona.

Whatsapp: +86 185 6019 6101Tel/WeCHat: +86 185 607 6010 2292

E-Lengolo-tsoibila: 391886440@qq.com Webosaete: https://www.annilte.net/