1, boleng ba thepa e tala, e ekelitsoeng lisebelisoa tse nchafalitsoeng le lisebelisoa tse senyang, tse bakang bophelo bo tlase, bophelo bo bokhutshwane ba litšebeletso bo bokhutshwane.

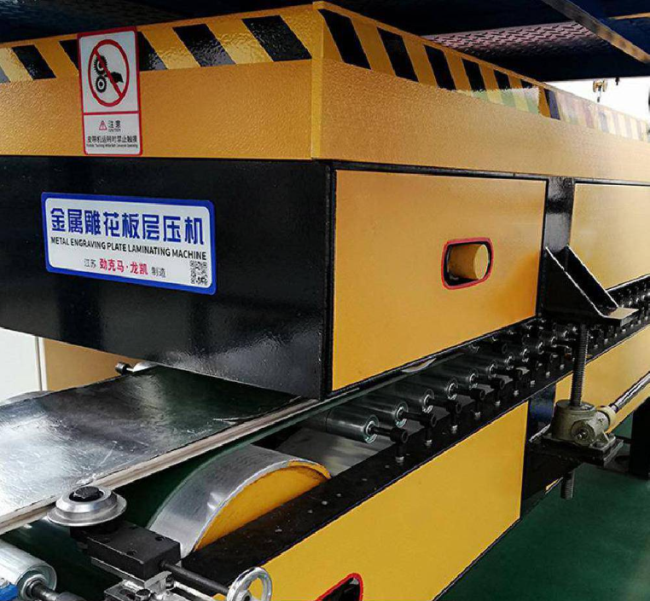

2, the production process is not pass, the bonding process is not mature, resulting in poor adhesion of the pressure strip due to the use of this belt in the pressure strip is very easy to fall off, not only will delay the production schedule, but also affect the quality of the metal engraved plate products, causing serious losses to the enterprise.

Joalokaha moetsi oa Belt ea Belt ea Belt, Adolte o ikemiselitse ho rarolla mathata a poleloana ea bareki, e le hore ho tiea ha BAR ea Amerika, le bareki ba bo sebelisa ka litlhaloso tse ntle.

Likarolo tsa Asai Metal e ngotsoe ka plumo ea Plete Conveler:

1, a sebelisa thepa e tala, lebanta ha le bonolo ntle le ho lahleheloa ke ho lahleheloa, ho ba matla le ho tšoarella;

2;

3, eketsa lisebelisoa tse sa feleng tsa polymer, mocheso o motle oa mocheso, mocheso o motle oa mocheso, o ka sebelisoa hangata ho 80 ℃ tikoloho ea mocheso o phahameng ntle le Deformation;

4, Ho amohela theknoloji ea litekanyetso, le nthabe e baleha hantle le ho qoba bothata ba ho hahamalla lebanta.

5, Prataetso ea Belt e Ncha ea Belt mohloli oa Belt, tlhahiso le boiphihlelo ba ho etsa lipatlisiso, ho latela tlhokahalo ea tloaelo e sa fetoheng.

Nako ea poso: Mar-11-2024